A team of researchers at Imperial, Cambridge and Manchester found a new way to extend LEDs lifespan

It has been over twenty years since Nobel Prize winning Professors Isamu Akasaki, Hiroshi Amano and Shuji Nakamura first invented blue LEDs in the early 1990s, sparking a revolution of highly-efficient lighting. Yet surprisingly many materials scientists are still trying to understand their properties. Now Dr Michelle Moram and her team at Imperial College London’s Department of Materials, in collaboration with team members at the University of Manchester and the University of Cambridge, have made a discovery that could help to make lighting our world even more efficient.

Whilst LEDs are extremely efficient compared to many other sources of lighting, they do suffer from defects called threading dislocations which degrade their performance and shorten their lifetimes. Although materials scientists have known about threading dislocations for some time, they have never, until now, been able to decipher why or how they behave and affect the electronic properties of the LED devices. Now Dr Moram’s team have discovered a difference in the composition around these defects which prevents threading dislocations from recombining non-radiatively.

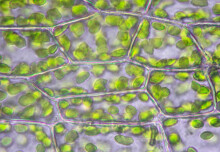

The light-emitting part of an LED is composed of indium gallium nitride (InGaN) which is an alloy of gallium nitride and indium nitride which is often grown on a sapphire substrate. InGaN is one of the most suitable materials to use as LEDs, yet it is also subject to a high density of threading dislocations. High dislocation density is unfortunately associated with efficiency losses in InGaN-based devices. It is therefore important to understand the local composition of InGaN around the cores to determine what might be causing them.

“So to understand more about it, we imaged indium gallium nitride films using a highly sensitive transmission electron microscope at the University of Manchester. The microscope is unlike anything I’ve used before,” says Sneha Rhode from the University of Cambridge, who is part of Dr Moram’s team. “There has been some speculation before, but this is the first experimental study which shows that yes, there is segregation of indium around the dislocation, and indium poor regions around the defect,” continues Ms Rhode.

The study shows local deviations in the alloy composition, with both indium rich and indium poor regions particularly close to the dislocations. Fortunately, now that it is easier to predict what causes the resilience of the GaN-based devices towards the harmful effects of dislocations, it might be possible to grow InGaN with fewer defects.

“This will allow us to produce much more efficient LEDs in the future, and I think it could be very soon as things are already happening. It could increase the efficiency, decrease the price and increase the performance. LEDs are used in many applications, including home lighting and water purification, so it will have huge widespread impact all over the world,” explains Mr Matthew Horton, another student in Dr Moram’s team working at Imperial College London..

“The next step for our research is to work out why we have only seen indium segregation in some of the defects and not all of them. Only fifty per cent of defects appear to have segregation at the moment, so we will probably do more characterisations to find out what is going on in the other half of these dislocations,” says Ms Rhode.

Whilst blue LEDs were invented over twenty years ago, their full potential is still only being unlocked now. Providing cheap, long-lasting and efficient lighting to billions of people worldwide as well as countless other uses in smartphones, TV screens and solar-powered water purification technology, they’re worth is unbounded. Therefore Dr Moram and her team’s work will undoubtedly touch the lives of almost everyone alive today in some shape or form.

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Caroline Detchenique

Department of Materials

Contact details

Email: press.office@imperial.ac.uk

Show all stories by this author