Chemical Engineering researchers have reported a robust approach to make polymer structures with UV light via Frontal Photopolymerisation (FPP).

As manufacturing gradually moves from large factories into smaller specialised units, the scientific research has delved ever deeper into the world of micro and nanofabrication with many fields of engineering concentrating their efforts on being able to fabricate smaller structures with increasing precision.

In a paper recently published in the journal Advanced Materials, researchers from Imperial report a new model that accurately predicts the fabrication of 3D patterned polymer materials through a process known as photopolymerisation. The model has the potential to be used in industry to more efficiently develop tunable and precisely constructed materials with wide applications ranging from the production of electronic materials, printing materials, optical and electro-optical materials, to the fabrication of devices and polymeric materials, adhesives and coating materials.

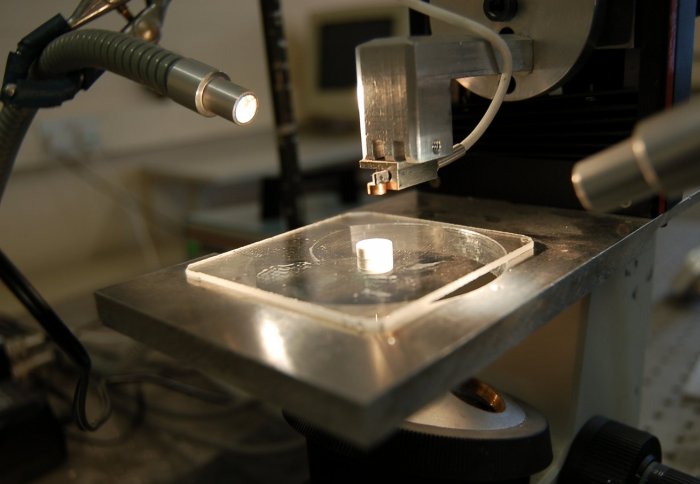

An illustration of the FPP mechanism

Photopolymerisation is one method of fabrication that is often used in applications ranging from dental materials to adhesives, coatings and lithography. In it, an ultraviolet beam of light is used to induce the formation of chemical bonds between monomers in a solution to form a cross-linked polymer. This method can be carried out at room temperature without using solvents and in very short time frames, making it very attractive in areas that require the quick fabrication of complex structures.

Frontal Photopolymerisation (FPP) is a special case of photopolymerisation which occurs when a narrow zone – or front – develops and progresses as a planar wave through the monomer material, driven by the light source. FPP is particularly desirable because of the control afforded and its versatility has been demonstrated in numerous areas from the synthesis of microparticles to manufacturing 3D microfluidic devices. There is however, a very wide range of materials and methods by which FPP can be carried out and no unified theory available to effectively predict the outcome of the process beforehand.

Now, by comparing a range of representative materials and the establishing the factors that determine the kinetics of photopolymerisation, researchers from the Polymers and Microfluidics Group have proposed a model that allows the prediction of the patterns that will be formed with FPP.

Lead researcher, Dr João Cabral, a Reader in Soft Matter at the Department of Chemical Engineering said, "The beauty of this model is that all that is required is the ability to measure parameters such as the temperature of the solution at different points and the intensity of the UV light incident on the liquid surface; both of which are easily obtained."

Some example of the patterns that can be predicted and obtained using FPP (scale bar = 500 microns)

The original paper was published in the journal Advanced Materials and can be found online via the Wiley Online Library.

The research was funded by the Engineering and Physical Sciences Research Council (EPSRC).

As manufacturing moves ever-so-slowly away from large factories into smaller specialised units, the scientific research has delved ever deeper into the world of micro and nanofabrication with many fields of engineering concentrating their efforts on being able to fabricate smaller structures with increasing precision.

PHOTO (Mechanism)

Photopolymerisation is one method of fabrication that is often used in applications ranging from dental materials to adhesives, coatings and lithography. In it, an ultraviolet beam of light is used to induce the formation of chemical bonds between monomers in a solution to form a cross-linked polymer. This method can be carried out at room temperature without using solvents and in very short time frames, making it very attractive in areas that require the quick fabrication of complex structures.

Frontal Photopolymerisation (FPP) (//www3.imperial.ac.uk/polymersandmicrofluidics/projects/frontalphotopolymerisation) is a special case of photopolymerisation which occurs when a narrow zone – or front – develops and progresses as a planar wave through the monomer material, driven by the light source. FPP is particularly desirable because of the control afforded and its versatility has been demonstrated in numerous areas from the synthesis of microparticles to manufacturing 3D microfluidic devices. There is however, a very wide range of materials and methods by which FPP can be carried out and no unified theory available to effectively predict the outcome of the process beforehand.

Now, by comparing a range of representative materials and the establishing the factors that determine the kinetics of photopolymerisation, Alessandro Vitale and Matthew Hennessey from the Polymers and Microfluidics Group (//www3.imperial.ac.uk/polymersandmicrofluidics) have proposed a model that allows us to predict the patterns that will be formed with FPP. All that is required is the ability to measure parameters such as the temperature of the solution at different points and the intensity of the UV light incident on the liquid surface; both of which are easily measurable.

The research promises to significantly simplify the process of FPP and enable much greater control over the final pattern that is fabricated. The team envisions that this method could yield great results in a variety of applications ranging from flexible electronics and biotechnology to advanced coatings and adhesives. With it, a future that allows every person to be able to custom-build objects and devices in the convenience of the home is perhaps another step closer.

The original paper was published in the journal Advanced Materials and can be found online via Wiley Online Library. (http://onlinelibrary.wiley.com/doi/10.1002/adma.201502607/full).

Article text (excluding photos or graphics) available under an Attribution-NonCommercial-ShareAlike Creative Commons license.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporters

Michael Panagopulos

Department of Chemical Engineering

Contact details

Email: press.office@imperial.ac.uk

Show all stories by this author

Mikhail Menezes

Department of Chemical Engineering

Contact details

Email: press.office@imperial.ac.uk

Show all stories by this author

Leave a comment

Your comment may be published, displaying your name as you provide it, unless you request otherwise. Your contact details will never be published.