Researchers at Imperial College London have successfully produced porous boron nitride with four times better adsorption properties than before.

Porous materials have high surface area due to their pore structure, which makes them perfect for a wide range of applications, for instance drug delivery, molecular separations, catalysis, gas storage, water or air treatment. Consequently, these materials are becoming increasingly important. Common types include: activated carbons, zeolites, metal-organic frameworks and – more recently – boron nitride. Despite having several exceptional properties (high chemical resistance, good thermal stability, high thermal conductivity and mechanical resistance), there has been very limited research into the properties and formation of porous boron nitride thus far.

This new approach provides a scalabe route to porous boron nitride production in the future.

– Dr Camille Petit

Lead author

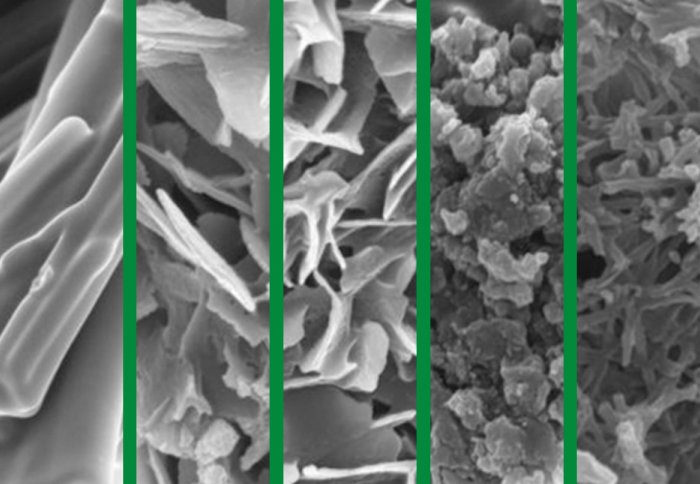

Researchers from the Department of Chemical Engineering and Department of Materials at Imperial College London have now developed a new method to produce boron nitride with tunable surface area, micro- and mesoporosity. The template-free method, which involves multiple nitrogen-containing precursors, uses gradually released gases to create high surface areas and micropores in the structure.

As there are no additional materials involved in the precursors, a cleaning or washing step is not required after the decomposition of nitrogen.Therefore, this method presents a simple and straightforward way of producing porous boron nitride. After creating the structure, the team used 3D tomography and other analytical tools to visualize and characterize the pore network in terms of chemistry, structure, porosity and morphology.

They found that the newly developed porous boron nitride structure had up to four times higher carbon dioxide uptake compared to previously reported materials, even after compressing the powder samples into pellets. The results, published in ACS Nano, are highly relevant to industry as they show an important new method to produce boron nitride in a cost-effective and simple way, while enabling tunable total and microporosity. Crucially, in developing this new method, the researchers have also fully characterized the resulting boron nitride structure, which will help in applications such as carbon capture or catalysis.

Reference

Sofia Marchesini, Catriona M. McGilvery, Josh Bailey, Camille Petit. Template-Free Synthesis of Highly Porous Boron Nitride: Insights into Pore Network Design and Impact on Gas Sorption. ACS Nano, 2017. DOI: 10.1021/acsnano.7b04219

[Article written by Dora Petra Olah, an Undergraduate student in the Department of Chemical Engineering.]

Article text (excluding photos or graphics) available under an Attribution-NonCommercial-ShareAlike Creative Commons license.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Ms Genevieve Timmins

Academic Services

Contact details

Email: g.timmins@imperial.ac.uk

Show all stories by this author

Leave a comment

Your comment may be published, displaying your name as you provide it, unless you request otherwise. Your contact details will never be published.